ets and helicopters fascinated Connie Hong ('12) as a little girl. She never realized she would one day be responsible for aircraft like those her father maintained in the U.S. Air Force or the airplanes her mom worked on for Lockheed Martin Aeronautics, then known as General Dynamics. Now Hong, who is forging her own career as a program planner at Lockheed Martin -- one of the world's largest defense contractors -- is part of a fleet of people responsible for keeping the company's military aircraft safe and in the sky.

"We have to know how to sustain an aircraft over time and maintain it for its life after we have built it," says Hong, a graduate of UNT's logistics program with a specialization in aviation. "We must work with our suppliers and manage staffing for the repairs. It's all about minimizing down time, improving efficiency and reducing costs."

"We have to know how to sustain an aircraft over time and maintain it for its life after we have built it," says Hong, a graduate of UNT's logistics program with a specialization in aviation. "We must work with our suppliers and manage staffing for the repairs. It's all about minimizing down time, improving efficiency and reducing costs."

Hong, like many others, turned to UNT's top-ranked logistics program for its national reputation in preparing students to manage supply chains effectively.

Best in class

UNT's supply chain management undergraduate program is ranked No. 3 in the nation on Software Advice's 2015 list, and after two consecutive wins of the Intermodal Association of North America's annual challenge and expo, a UNT team took the top prize at the IANA-University of North Florida annual case competition this year for the first time.

UNT ranked sixth on Gartner Research's list of top U.S. supply chain under-graduate programs and 24th on its graduate programs list. And soon, the aviation logistics program will expand, in a partnership with Tarrant County College to propel community college students to a four-year degree and a career as a pilot.

"I was impressed with UNT from the start," says Hong, who was able to gain hands-on learning through an internship at the Denton Municipal Airport. She says with the Dallas-Fort Worth area's seven interstate highways, seven freight rail lines and three big airports -- DFW International Airport, Alliance Airport and Love Field -- UNT logistics learners are poised for their careers in an ever-expanding logistics hub.

"There is definitely a demand for UNT graduates," Hong says.

Jason Campbell ('00, '05 M.B.A.), transportation and logistics manager for Martin Marietta, agrees.

Jason Campbell ('00, '05 M.B.A.), transportation and logistics manager for Martin Marietta, agrees.

"There are tremendous opportunities for logistics careers in our region," he says.

Campbell got his start as an undergraduate working part time as a concrete dispatcher 17 years ago for TXI, or Texas Industries, one of the largest construction materials producers in the U.S. He's held many positions in the company and now manages inbound and outbound logistics for the DFW Ready Mix division of Martin Marietta, a heavyweight in the manufacture of construction and building materials that merged with TXI in 2014.

They deliver the pre-mixed concrete up to a thousand times a day throughout the Dallas-Fort Worth area. The variable weather, number of delivery trucks, traffic patterns and unpredictable needs of clients leave little room logistically for errors.

"It ultimately doesn't matter how much product you can make if you can't move it," says Campbell, who wrote his master's thesis on centralized distribution of ready-mixed concrete. "The challenge of our finished product is, once it's mixed, you only have so long to deliver. You can't return it, put it on a shelf or stockpile it."

Lessons learned

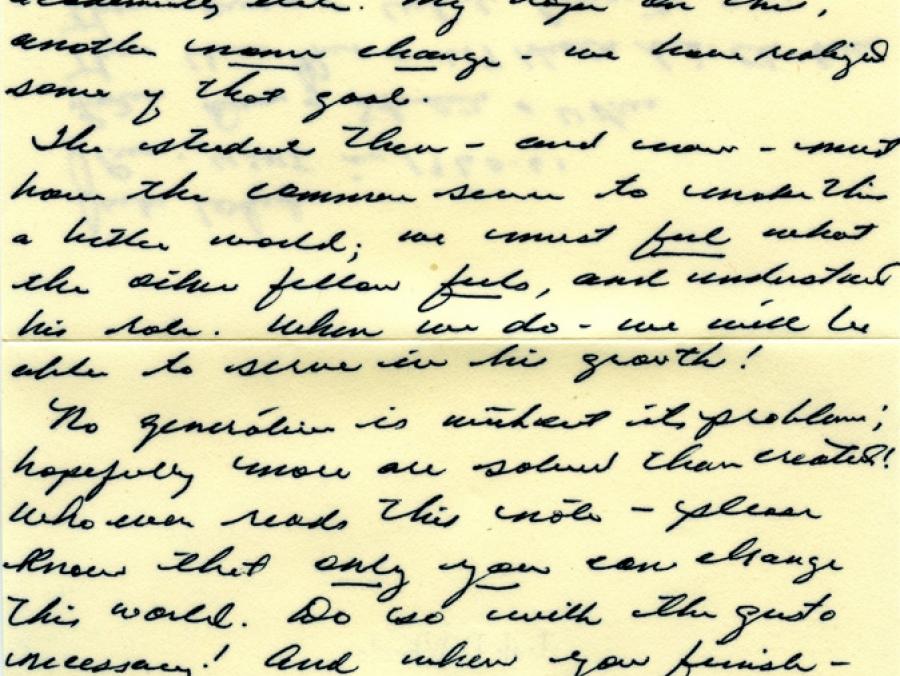

Campbell recalls "the beer game," a lesson in the bullwhip effect shared by Terry Pohlen, associate professor of logistics, showing how small changes become amplified along a supply chain. Assigned a hypothetical beer delivery for a football game, students were given roles for everything from sourcing materials to client ordering. They all needed someone else in the supply chain to complete their parts. They didn't know that one student was told to purposely sabotage the game.

"It made me think of logistics in a different way and consider the impact that outside forces can have on your supply chain," Campbell says. "It stuck with me."

George Fegan ('13), a railcar equipment specialist at BNSF in Fort Worth, says UNT's program helped him learn about the importance of hands-on experience, which helped him develop his talents.

George Fegan ('13), a railcar equipment specialist at BNSF in Fort Worth, says UNT's program helped him learn about the importance of hands-on experience, which helped him develop his talents.

He began in the management trainee program at BNSF, an industry leader in logistics transportation and the second- largest freight railroad in North America. That training role eventually led to his current position, in which he oversees and manages a fleet of railcars.

The required internship program has made UNT logistics graduates highly competitive in the field.

"They have near perfect job placement," says Fegan, who started work two days after graduating with a bachelor's degree in logistics and professional certification from the American Society of Transportation and Logistics. "I realized how competitive the degree program is on a national scale."

It was as a UNT student at Operation Stimulus, a nationwide conference and logistics case competition, that Fegan first networked with recruiters from BNSF. He also was a member of the supply chain management organization and met logistics leaders throughout the U.S.

"The power of networking is crucial," says Beth Mars ('06), manager of the transportation, technology and network optimization team for Frito-Lay, a division of PepsiCo that manufactures snack goods. "Students should take every opportunity they have to meet people in the industry and learn from them -- that's invaluable. in the workplace."

"The power of networking is crucial," says Beth Mars ('06), manager of the transportation, technology and network optimization team for Frito-Lay, a division of PepsiCo that manufactures snack goods. "Students should take every opportunity they have to meet people in the industry and learn from them -- that's invaluable. in the workplace."

Mars made friends with fellow students in the logistics student association. They still keep in contact, nearly 10 years later.

"We run problems by each other and network when we know of someone looking for a job," says Mars, who received the certified transportation professional top graduate award from the National Private Truck Council in 2014.

Rich collaborations

At Frito-Lay, Mars and a team of network coordinators are responsible for transportation planning, network efficiency and technology solutions for 31 traffic centers in the U.S. and Canada.

She began working at the Plano-based company 10 years ago, helping to secure third-party freight carriers, and has since worked to improve supply chain efficiency by managing data in financial accounts and optimizing the freight network.

"I work cross functionally with data to come up with new and innovative ways to do the things we do better: reduce miles from the transportation network, enhance routing systems," Mars says.

Along the way, she's learned that logistics is more than delivering goods from one place to another and crunching numbers. For example, weather events like a hurricane can be crippling to the supply chain.

"We have to redeploy our assets and provide products where they're most needed," she says. "And keep employees and consumers out of harm's way."

Mars says UNT prepares students to be thought leaders for logistics in the North Texas region and beyond. And industry connections make graduates marketable.

She often returns to campus as the UNT liaison for Frito-Lay's supply chain steering committee and has partnered with transportation students on class projects.

"They've come up with great ideas and solved problems for us," she says, adding that she also speaks to student groups.

"I hope to help students gain a foothold in their careers," Mars says, "the way that UNT helped me."